Model: QDY 10~75t, YZ 100~800t

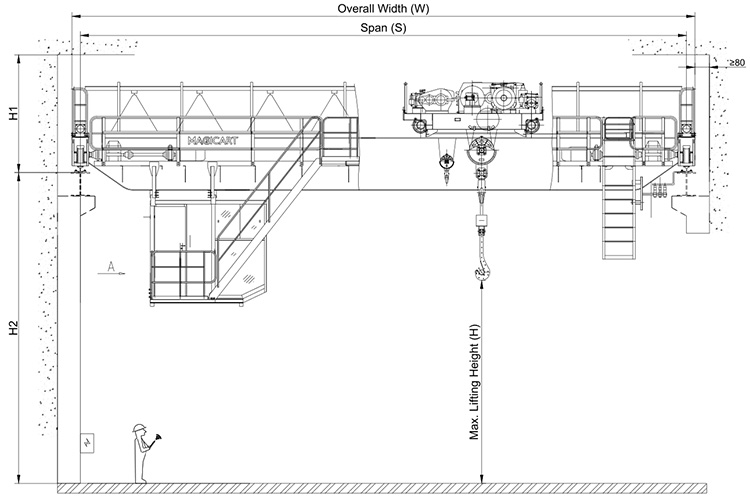

Load Capacity: 10~800t, customized

Span: 15~110m, customized

Lifting Height: 8~110m, customized

Class: standard A5 / A6 / A7 / A8

Powered via bus bar system

Metallurgical cranes are mainly suitable for special cranes for metal smelting, rolling and thermal processing.

MAGICART’s ladle crane are built to be safe and efficient while working with molten metal in foundries and steel mills. These cranes come with state-of-the-art safety features and are very solidly built allowing them to operate even in extremely hot and difficult conditions. Where control is very precise and the lifting capacity is very high, our ladle cranes are sure to operate reliably in very demanding industrial environments. The ladle crane of MAGICART brand are tailored according to the customers’ needs, thus being the ideal tool for the molten metal handling operation. Count on MAGICART for premium ladle crane solutions.

Double sets of independent action brakes.

High temperature resistant cable.

| Cap (t) | 5 | 10 | 16 | 20 | 32 | 50 |

| Span (m) | 10.5-31.5 | 10.5-31.5 | 10.5-31.5 | 10.5-31.5 | 13.5-31.5 | 13.5-31.5 |

| Lifting Height (m) | 16 | 20 | 16 | 12 | 16 | 12 |

| Max. Wheel Load (KN) | 143 | 181 | 229 | 253 | 354 | 481 |

| Total Power (KW) | 27.1 | 45.5 | 59.7 | 79.7 | 90.5 | 130.5 |

| Hositing Speed (m/min) | 13 | 12.9 | 10.9 | 9.8 | 7.7 | 6.3 |

| Crab Travelling Speed (m/min) | 39.5 | 35.2 | 31 | 37 | 37.6 | 31.8 |

| Crane Travelling Speed(m/min) | 95.7 | 93.7 | 90.4 | 90.9 | 77 | 77.8 |

| Power Sourse | Three phase.AC 380V 50HZ | |||||

Technical Support | Customized Design | Project Budget | Offer for Bidding | Contracting | Fast Services...

Call +86 373 5853707 +86 17337369287to enjoy a good experience here!

Our Sales Engineer will contact with you within 12 hours!

Copyright © 2025 Xinxiang MAGICART Cranes CO., LTD.